Venturi Tube Flow Measurements

About Venturi Tube:

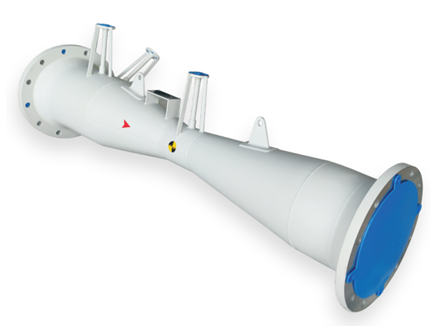

A venturi tube is a flow measurement device that utilizes the principle of Bernoulli’s equation to accurately measure the flow rate of fluids.

It consists of a tapered tube with a narrow throat in the middle, creating a constriction.

Image Credit: Electronet

As the fluid flows through the venturi tube, its velocity increases, leading to a decrease in pressure.

This pressure differential is used to determine the flow rate. Venturi tubes offer accurate measurements, low-pressure loss, and compatibility with various fluids, making them widely used in industries such as oil and gas, chemical processing, and water treatment.

Working Principle of Venturi Tube:

The working principle of a venturi tube is based on Bernoulli’s equation, which is as the velocity of a fluid increases, its pressure decreases.

A Venturi Tube is nothing but a tubular section with a constriction in it.

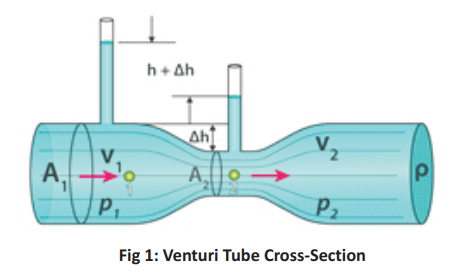

It has a convergent nozzle section towards upstream and a divergent diffuser section towards downstream which is responsible for creating a Venturi effect in the flowing fluid.

The Venturi Tube is placed inside the pipe or positioned between two flanges. It is ensured that the pipeline is completely filled with a fluid, while operating the device.

A differential pressure sensor is attached between the two points, convergent and divergent sections, to determine the fluids’ differential pressure.

The DP sensor measures the pressure of the fluid flow, upstream and downstream. The differential pressure (P1-P2) is proportional to the flow rate and can be determined by mathematical equations and appropriate calibration as shown in Fig 1.

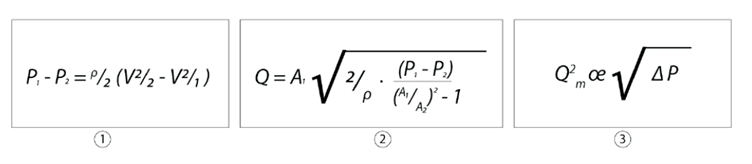

Bernoulli described this relation between differential pressure and volumetric flow rate by a mathematical equation.

Where ñ is density of fluid. The differential pressure generated, ÄP, is proportional to the square of mass flow rate Qm. In simple terms, or a given size of restriction, higher the Äp, higher is the flow rate.

Type of Venturi Tubes:

-

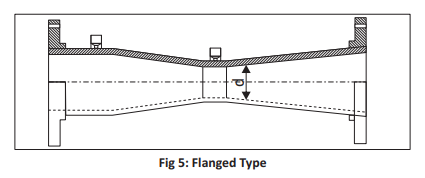

Flanged Type:

As shown in Fig 5, Flanged type venturi tubes are a specialized variation of venturi tubes that incorporate flanges for convenient installation and connection within a piping system.

These tubes feature flanges attached to the inlet and outlet sections, allowing them to be securely bolted between corresponding pipe flanges.

This design facilitates a robust and leak-proof connection, ensuring reliable and accurate flow measurement. -

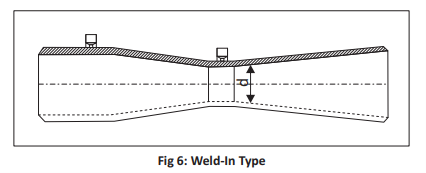

Weld-In Type:

As shown in Fig 6, Weld-In type venturi tubes are a specialized variation of venturi tubes designed for permanent installation within a piping system.

These venturi tubes feature a configuration that allows them to be welded directly into the pipeline, ensuring a robust and permanent connection. -

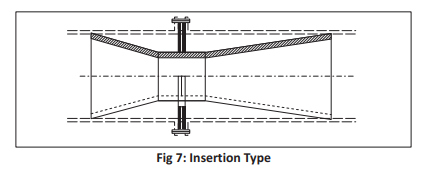

Insertion Type:

As shown in Fig 7, Insertion type venturi tubes are a specialized variation of venturi tubes designed for easy insertion into existing piping systems without the need for cutting or welding.

These venturi tubes feature a unique design that allows them to be inserted through a tap or valve opening in the pipeline, making them ideal for retrofitting or temporary flow measurement applications.

Applications of Venturi Tube:

Flow measurement: Venturi tubes are commonly used for accurate and reliable flow rate measurement in various industries. They provide a pressure differential across the constriction, which can be correlated to the flow rate of the fluid passing through the tube. Venturi tubes are particularly effective for measuring high-velocity flows and can handle a wide range of fluid types.

Fluid mixing: Venturi tubes can be used for injecting and mixing chemicals or additives into a fluid stream. By introducing the additive through a side port in the tube, the Venturi effect creates a vacuum that draws the additive into the flowing fluid, facilitating thorough mixing.

Pressure regulation: Venturi tubes can be employed as pressure regulators in systems where a specific pressure drop is required. By adjusting the throat diameter or utilizing multiple stages, venturi tubes can help control and regulate the pressure within a fluid system.

Filtration systems: Venturi tubes can be integrated into filtration systems to create a vacuum or suction effect that assists in drawing and filtering out particulates or impurities from the fluid stream. The Venturi effect aids in enhancing the filtration efficiency and maintaining a clean fluid flow.

Ejectors and vacuum systems: Venturi tubes can be utilized as ejectors or part of vacuum systems to generate suction or vacuum. By utilizing the Venturi effect, these systems can effectively extract gases, vapors, or other substances from a specific area.

Industrial processes: Venturi tubes find applications in various industrial processes where accurate flow measurement, pressure regulation, or fluid mixing is required. They are widely used in industries such as oil and gas, chemical processing, water treatment, HVAC systems, and more.

Advantages of Venturi Tubes:

Accurate flow measurement: Venturi tubes provide accurate and reliable flow rate measurements, particularly for high-velocity flows.

Low-pressure loss: Compared to other flow measurement devices, Venturi tubes cause minimal pressure loss, ensuring efficient fluid flow through the system.

Wide range of fluid compatibility: Venturi tubes can handle a wide range of fluid types, including liquids, gases, and even slurries.

Simple and robust design: Venturi tubes have a straightforward design with no moving parts, making them durable and requiring minimal maintenance.

Cost-effective: Venturi tubes are generally cost-effective compared to other flow measurement devices, making them a popular choice in many applications.

Disadvantages of Venturi Tubes:

Limited turndown ratio: Venturi tubes may have a limited turndown ratio, meaning they may not accurately measure low flow rates compared to their maximum capacity.

Size and space requirements: Venturi tubes can be relatively large in size, requiring sufficient space for installation, which may not be suitable for compact systems.

Sensitivity to upstream disturbances: Venturi tubes can be sensitive to upstream disturbances, such as uneven flow profiles or obstructions, which can affect their accuracy.

Calibration and installation considerations: Proper calibration and installation are crucial for accurate flow measurements with Venturi tubes, requiring expertise and care during setup.

Potential for clogging: In applications where fluids contain solid particles or debris, Venturi tubes may be prone to clogging or blockages, affecting their performance. Regular maintenance and cleaning may be necessary in such cases.

Thanks for reading!! Happy Learning!!

I hope you like above blog. There is no cost associated in sharing the article in your social media. Thanks for reading!! Happy Learning!!