How does an Ultrasonic Level Transmitter work?

The ultrasonic level transmitter is a preferred option for measuring water levels in open sumps, as it is a non-contact type of level transmitter widely utilized for continuous level measurement across various industries.

Image Credit: Electronet India

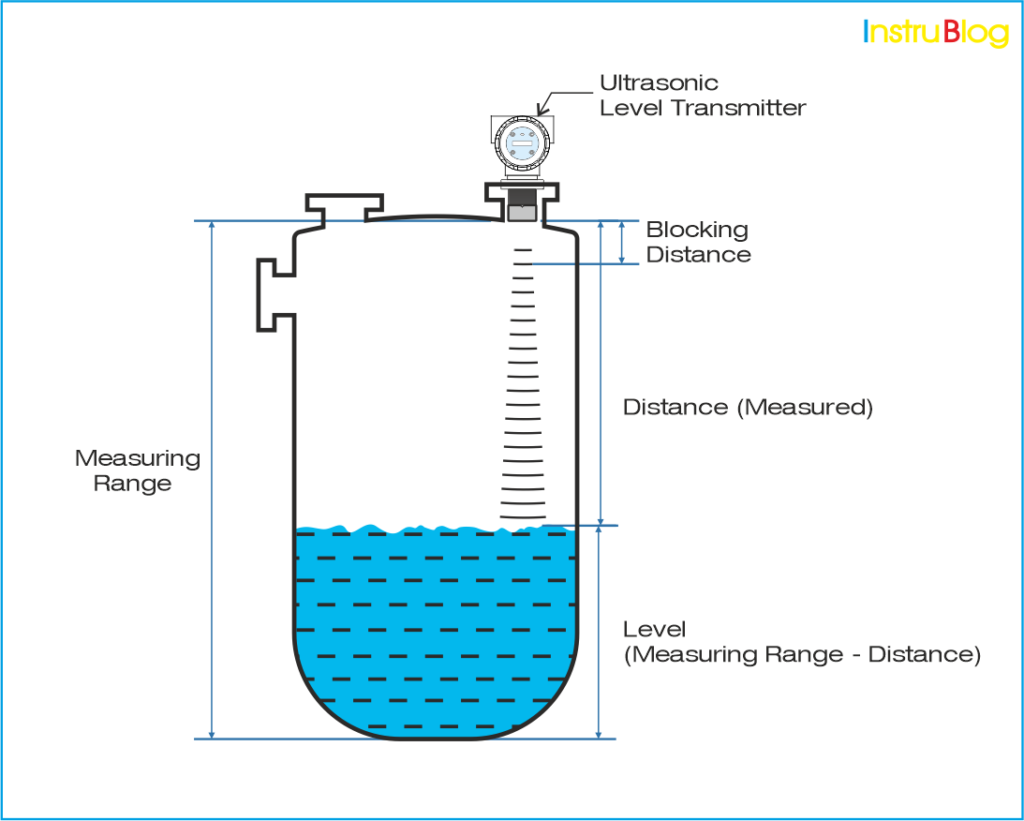

The ultrasonic level transmitter is positioned at the upper portion of the tank requiring level measurement. It emits ultrasonic waves that are directed towards the top surface of the material within the tank.

Subsequently, these waves reflect off the material and return to the transmitter. Equipped with a microprocessor, the transmitter precisely calculates the duration taken for the ultrasonic waves to make the round trip.

Using a simple formula of distance.

For Example: Distance = (speed of ultrasonic waves X time taken) / 2

By measuring the time taken for the ultrasonic waves to travel and return, we obtain the distance between the ultrasonic level transmitter and the material in the tank. To ensure accurate measurements, a blocking distance parameter is set in each ultrasonic level transmitter.

This parameter defines a short range near the transmitter that is disregarded if the waves bounce back from within this distance. Additionally, the tank height parameter is entered during configuration to provide the necessary information about the overall height of the tank.

From the figure,

Measuring Range = Distance + Level

The ultrasonic level transmitter utilizes the speed-distance relationship (speed = distance/time) to calculate the level measurement. This calculation takes place internally within the ultrasonic level transmitter using a built-in microprocessor.

The generation of ultrasonic waves is achieved through a piezoelectric crystal. This crystal converts electrical energy into ultrasonic waves, which can be produced at various frequencies ranging from 15 to 200 kHz. These waves are categorized as mechanical waves, as they require a medium to travel through.

To facilitate the transmission of ultrasonic waves, the ultrasonic level transmitter is suitable for tanks containing air or pressurized mediums. However, it is not applicable for vacuum applications, as ultrasonic waves cannot propagate through a vacuum. Effluent Treatment Plants commonly employ ultrasonic level transmitters for precise water level measurements in sumps.

Advantages of Ultrasonic Level Transmitter

- The ultrasonic level transmitter allows for level detection without the need for physical contact with the medium, offering non-contact measurement capabilities.

- It boasts a generous measuring range of up to 6 meters, making it suitable for a wide range of applications.

- This type of transmitter is versatile and capable of detecting various objects, including liquid levels, solid levels, foam levels, and more.

- Thanks to its design without any moving parts, ultrasonic level transmitters require minimal maintenance, providing a nearly maintenance-free solution.

- Configuring ultrasonic level transmitters is a straightforward process. Only a few essential parameters, such as tank height, blocking distance, and damping, need to be set to enable the basic functionality of the transmitter.

- Compared to other non-contact level transmitters like radar type transmitters, ultrasonic level transmitters offer a cost-effective solution with lower overall costs.

Disadvantages of Ultrasonic Level Transmitter

- Yes !! That’s Right, an ultrasonic level transmitter cannot be used in vacuum service as ultrasonic waves, being mechanical waves, require a medium to propagate.

- In situations where the medium absorbs the ultrasonic waves, the performance of the ultrasonic level transmitter is compromised, making it unsuitable for such applications.

- Temperature variations affect the speed of ultrasonic waves, leading to changes in the calculated height measurement. Therefore, temperature compensation is essential to ensure accurate readings.

- Due to the sensor being composed of a specific type of polymer, ultrasonic level transmitters are not suitable for use in high-temperature environments.

- Moisture droplets can sometimes adhere to the sensor tip, resulting in incorrect readings, often showing 100% level. In such cases, it becomes necessary to remove and clean the ultrasonic level transmitter to restore proper functionality.

Applications of Ultrasonic Level Transmitter

- Food & Beverage industry

- Chemical industry

- Tank water level measurement

- Open tank level measurement

I hope you like above blog. There is no cost associated in sharing the article in your social media. Thanks for reading!! Happy Learning!!

1 Comment