What is a Radar type level transmitter?

One of the commonly employed methods for continuous level measurement is radar-based level measurement. The selection between radar and ultrasonic level transmitters can often lead to confusion. However, fret not, as an upcoming article will delve into this very topic.

Radar level transmitters find widespread usage in the petroleum industry and other process industries. They are particularly suitable for applications in power plants, acid and caustic tanks, crude vessels, and storage tanks.

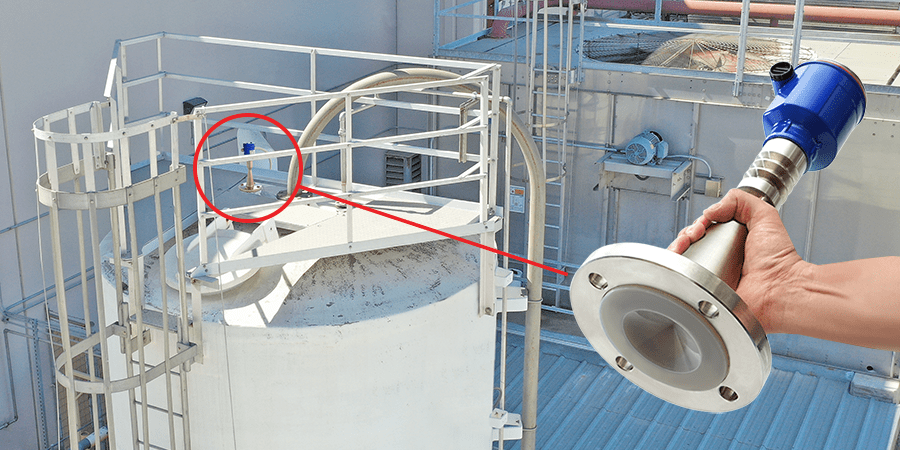

Image Credit: flowline.com

Operating on the principle of time of flight, radar level transmitters utilize a radar antenna positioned atop the tank to emit radar waves towards the material. These waves travel to the tank and return upon reflection. The antenna then receives the returning waves, and a microprocessor records the time taken for the travel. The speed of radar waves is already a known factor.

Using the formula of speed = distance/time we can calculate the distance.

Type of Radar Level Transmitters

There are two types of Radar level transmitters:

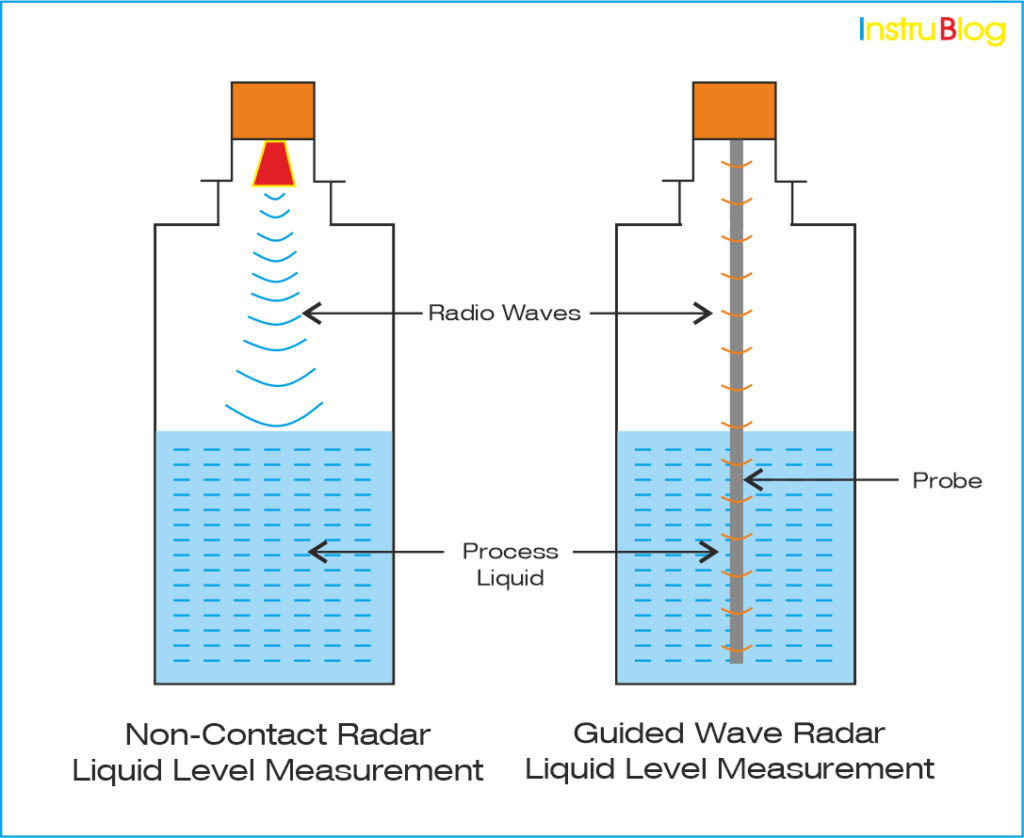

1. Contact type radar level transmitter

2. Non-contact type radar level transmitter

Contact type radar level transmitter

The construction of a contact-type radar level transmitter includes a probe that is linked to the transmitter, which comprises an antenna and a microprocessor.

The antenna emits radar waves towards the tank by means of the guiding probe. Upon reaching the material, a portion of the radar waves is reflected back, while the remaining portion continues to travel towards the tank bottom.

Once it reaches the bottom, it reflects back to the transmitter, resulting in the creation of an echo waveform. This echo waveform proves valuable in determining the interface or boundary within the tank.

Non-contact type radar level transmitter

The non-contact type radar level transmitter consists of an antenna and a microprocessor.

The antenna transmits radar waves into the tank, which are then reflected back from the material and received by the transmitter. The microprocessor calculates the distance based on the time taken for the radar waves to return and the known speed of radar waves.

In comparison, contactless radar experiences greater signal loss compared to guided wave radar, primarily due to the natural tendency of electromagnetic radiation to disperse into space. Waveguides help mitigate this signal loss by directing radio energy along a direct path with the aid of a probe.

The dielectric constant of the material is an important consideration when using radar level transmitters. For proper measurement and echo generation, there should be a difference of at least 5-8 in the dielectric constant between the media being measured. Otherwise, the radar waves may not produce a distinct echo.

Advantages of Radar type level transmitter

- Non-contact radar level transmitters are particularly well-suited for applications involving highly corrosive liquids, as they do not require direct contact with the medium.

- Radar level transmitters are versatile and can effectively measure levels in various substances, including liquids, solids, slurries, and interfaces.

- Due to their design without moving parts, radar level transmitters require minimal maintenance, resulting in low maintenance requirements.

- The measurement accuracy of radar level transmitters remains unaffected by changes in liquid properties such as density, temperature, and pressure. The primary factor impacting the measurement is the dielectric change of the medium.

- Compared to other level measurement techniques, radar-type level transmitters offer excellent response and accuracy, making them a reliable choice for level measurement applications.

Limitations of Radar type level transmitter

- Changes in the permittivity of the material being measured can impact the readings obtained by radar level transmitters.

- In the case of contact radar, echoes can be formed when material adheres to the probe, leading to incorrect measurements. To rectify this, the probe needs to be removed, cleaned, and then reinstalled.

- Even with non-contact radar, cleaning may be necessary if there is any buildup or obstruction on the antenna.

- For accurate interface measurements, there should be a minimum difference of 5-8 units in permittivity between the materials. Otherwise, the interface echo may not be measured correctly.

- Proper installation and troubleshooting of radar level transmitters may require specialized training specific to the product manufacturer, along with a laptop PC equipped with the manufacturer’s software.

- Calibration of radar-type level transmitters can be a somewhat challenging procedure that requires careful attention to ensure accurate measurements.

Manufacturers of Radar Type Level Transmitters

Please find below some companies which are manufacturing radar type level transmitters.

| Manufacturer | Website |

|---|---|

| Emerson Automation Solutions | https://www.emerson.com/ |

| Siemens | https://new.siemens.com/ |

| Endress+Hauser | https://www.endress.com/ |

| ABB | https://global.abb/group/en |

| VEGA | https://www.vega.com/ |

| Yokogawa | https://www.yokogawa.com/ |

| KROHNE | https://krohne.com/ |

| Honeywell Process Solutions | https://www.honeywellprocess.com/ |

| Magnetrol | https://www.magnetrol.com/ |

| Schneider Electric | https://www.se.com/ |

| FlowLine | https://www.flowline.com/ |

| Electronet India | https://www.eeplindia.com |

I hope you like above blog. There is no cost associated in sharing the article in your social media. Thanks for reading!! Happy Learning!!