How Ultrasonic Flow Meter Works?

The ultrasonic flow meter, extensively utilized for precise volumetric flow measurement, shares similarities with magnetic flow meters by not obstructing the flow and causing zero pressure drop in the fluid as it passes through the line.

Working Principle of Ultrasonic Flow Meter?

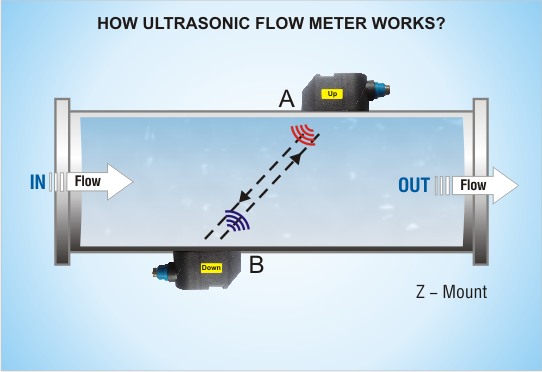

Ultrasonic flow meter are based on Transit Time Technology. The transmitter processes the signals from the wave & its reflections determine the flow rate. Transit time meters transmit & receive ultrasonic waves in both the directions within the pipe.

Ultrasonic flow meters operate using the transit-time differential method technology. A sound wave travelling in the direction of flow of the product is propagated at a faster rate than one travelling against the flow (vAB > vBA). Transit times tAB and tBA are measured continuously. The difference (tBA-tAB) in time travelled by the two ultrasonic waves is directly proportional to the mean flow velocity (vm).

Where,

tAB is Time required for ultrasonic wave to travel from Sensor A to sensor B.

tBA is Time required for ultrasonic wave to travel from Sensor B to sensor A.

Image Credit : Electronet India

An ultrasonic flow meter measures the velocity of a fluid with ultrasound to calculate volume flow.

Using ultrasonic transducers, the flow meter can measure the average velocity along the path of an emitted beam of ultrasound, by averaging the difference in measured transit time between the pulses of ultrasound propagating into and against the direction of the flow or by measuring the frequency shift from the Doppler effect.

Ultrasonic flow meters are affected by the acoustic properties of the fluid and can be impacted by temperature, density, viscosity and suspended particulates depending on the exact flow meter.

Types of Ultrasonic Flow Meter?

There are two types of Ultrasonic Flow Meters available

1) works on the principle of the famous Doppler effect

2) works on the time transit principle

Let us explore both types in details.

1. Time Transit Ultrasonic Flow Meter

The time transit ultrasonic flow meter, known for its broad range of applications in flow measurement, operates on a very simple principle. It utilizes ultrasonic waves based on the time transit principle and is available in two different configurations:

A. Having 2 wave transducer receivers or more pairs of transducers receivers

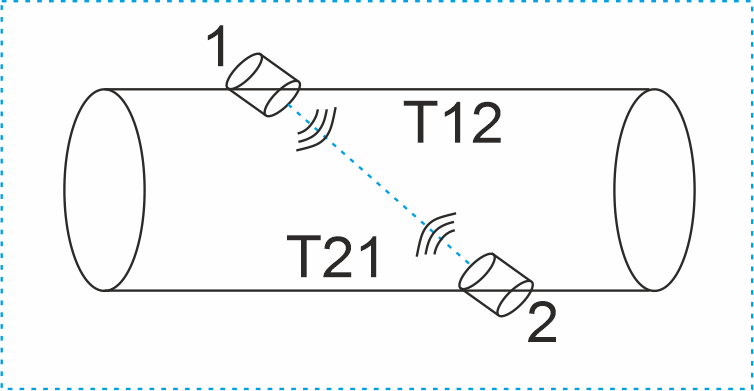

In this method, 2 transducers / sensors receivers are installed in line as shown below figure.

A transducer or sensor receiver is capable of both transmitting and receiving signals. During the measurement process, the first transducer receiver emits ultrasonic waves while the second trans receiver captures them.

The flow meter processor calculates the time interval between these actions. Subsequently, the second transducer receiver transmits ultrasonic waves, which are then received by the first transducer receiver. The flow meter processor once again measures the time elapsed during this phase.

In scenarios where the flow direction is from the first trans receiver to the second trans receiver, the travel time for ultrasonic waves between the two receivers will be shorter compared to the time required for waves to travel from the second trans receiver to the first transducer receiver.

By considering both time intervals, the processor accurately determines the fluid flow through the pipe.

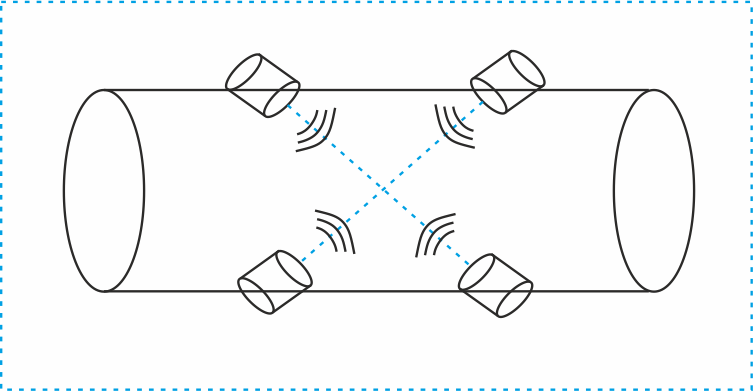

The accuracy of the measurement depends on the number of transducer receivers employed. To achieve higher measurement accuracy, it is essential to use a greater number of transducer receivers.

In the provided image, two pairs of trans receivers are utilized, and they function similarly to the single pair discussed earlier.

By employing multiple pairs, the ultrasonic flow meter enhances the accuracy of the system as it takes an average of the readings obtained from each pair.

B. Clamp-on mounted ultrasonic flow meter

The clamp-on ultrasonic flow meter, as the name suggests, involves mounting external sensors on the pipe. This type of flow meter operates on the same principle as the transit time ultrasonic flow meter.

The primary requirement for this meter is knowledge of the pipe’s thickness onto which it will be mounted.

Image Credit : Electronet

The clamp-on ultrasonic flow meter is particularly well-suited for temporary flow measurements. It offers the advantage of non-intrusive installation, eliminating the need for pipe modifications or interruptions to the flow. This makes it a convenient choice for situations where temporary or portable flow measurement is required.

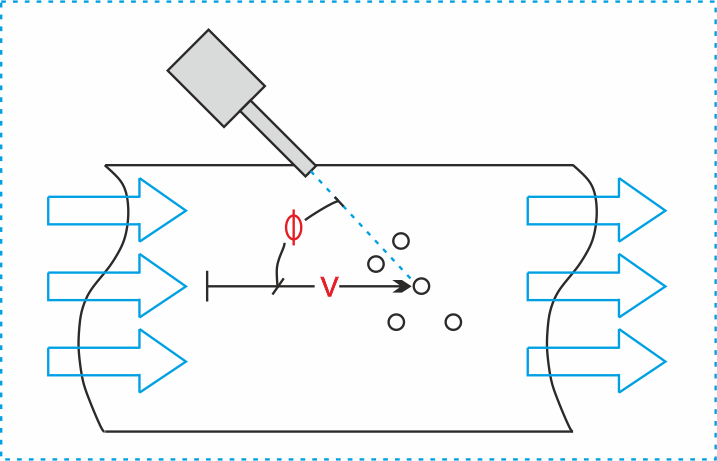

2. Doppler Effect Ultrasonic Flow Meter

The Doppler effect ultrasonic flow meter operates by transmitting ultrasonic waves into the pipe, which are then reflected back from bubbles or particles present in the fluid.

As these waves reflect back, they undergo a frequency shift. This change in frequency, known as the Doppler effect, occurs due to the motion of the reflecting particles or bubbles in the fluid.

The formula to calculate the velocity of the fluid using the Doppler effect in a Doppler effect ultrasonic flow meter is as follows:

V = (f * c) / (2 * f0 * cos(θ))

Where:

- V is the velocity of the fluid

- f is the frequency shift (the difference between the transmitted frequency and the received frequency)

- c is the speed of sound in the fluid

- f0 is the transmitted frequency

- θ is the angle between the ultrasonic beam and the direction of fluid flow

It’s important to note that this formula assumes a simplified scenario with a single-frequency ultrasound wave and a steady flow profile. In practical applications, additional factors such as multiple reflections, beam angles, and flow disturbances may need to be considered for more accurate measurements.

Applications of ultrasonic flow meter

- Suitable for measuring the flow of dirty liquids or wastewater, where the presence of impurities or contaminants would hinder the use of contact-type flow meters.

- Ideal for measuring the flow of chemicals requiring high purity, as the non-contact nature of this flow meter eliminates the risk of contamination.

- Effective in measuring the flow of fluids containing solid particles, as the flow meter does not come into direct contact with the fluid, reducing the risk of clogging or damage.

- Well-suited for measuring the flow of fluids with bubbles, as the non-intrusive nature of the flow meter allows accurate measurements without disrupting the bubble formation or flow dynamics.

Advantages of Ultrasonic flow meters

- Ultrasonic flow meters are a superior alternative to magnetic flow meters as they do not have the limitation of requiring a minimum conductivity for accurate flow measurement.

- They are well-suited for measuring flow in dirty liquids and slurries, overcoming the challenges faced by magnetic flow meters in such applications.

- Ultrasonic flow meters do not have any moving parts, resulting in negligible pressure loss within the flowing fluid and reducing the potential for maintenance issues.

- Due to the absence of moving parts, ultrasonic flow meters require less maintenance compared to other types of flow meters.

- Ultrasonic flow meters are bi-directional, enabling them to accurately measure flow in both directions.

- Clamp-on ultrasonic flow meters can be installed without causing any process disturbance, making them convenient and non-intrusive for flow measurement applications.

Limitations of Ultrasonic flow meters

- Ultrasonic flow meters may not be suitable for fluids with high turbulent flow due to the potential interference and disturbances caused by turbulent conditions.

- Compared to other types of flow meters, ultrasonic flow meters can be relatively expensive, making them a costlier option for flow measurement applications.

- The accuracy of ultrasonic flow meters can be influenced by the temperature of the fluid being measured. The speed of the waves used in measurement can change with temperature variations, affecting the accuracy of the flow readings.

I hope you like above blog. There is no cost associated in sharing the article in your social media. Thanks for reading!! Happy Learning!!