Table of Contents

ToggleAbout Limit Switches

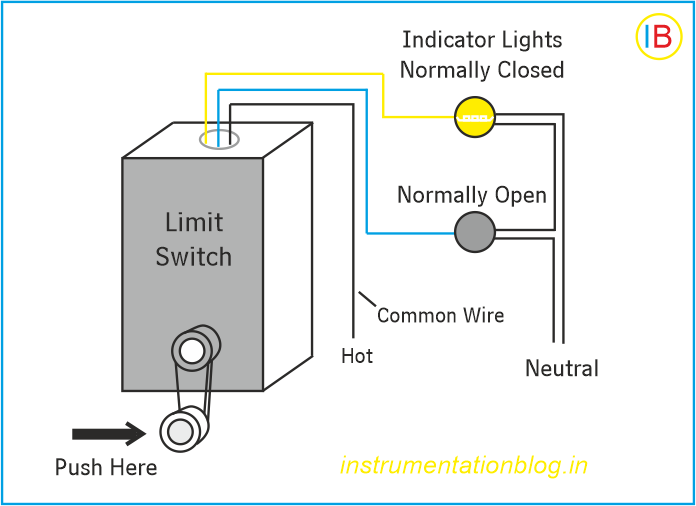

Lets learn What is a Limit Switch ? A Limit Switch is an electrical switch that is activated either by the movement of a machine component or the presence of an object, serving various purposes such as machine control, safety interlocking, or object counting at a specific location.

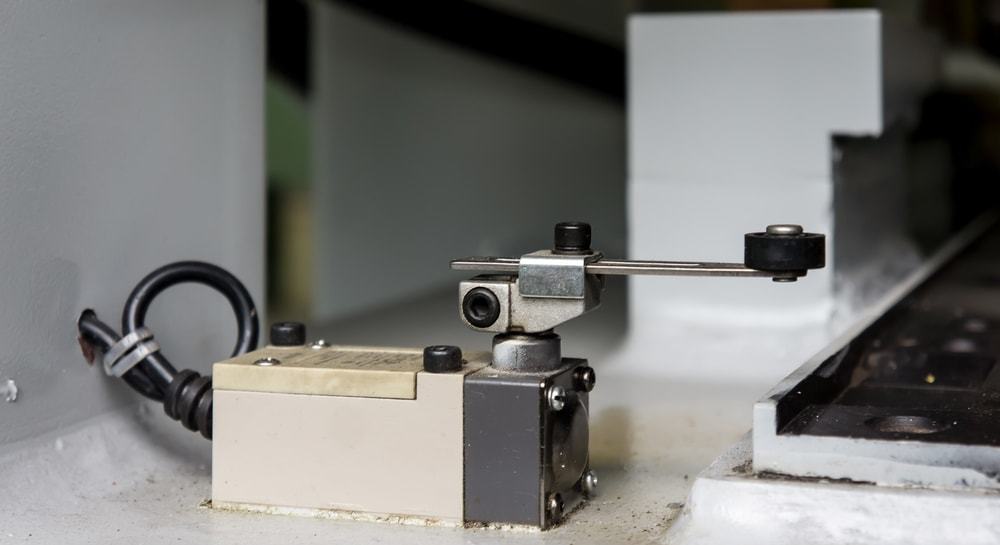

Standardized limit switches are essential industrial control components that are manufactured with a range of operator types, such as lever, roller plunger, and whisker types. These switches are designed to meet industry standards and provide reliable operation in various applications.

In some cases, limit switches can be mechanically operated directly by the motion of the operating lever, ensuring precise control and responsiveness. Additionally, a reed switch can be employed to detect the proximity of a magnet that is mounted on a moving part, allowing for accurate positioning and detection capabilities.

By utilizing different operator types and incorporating innovative technologies, standardized limit switches offer versatility and adaptability for use in diverse industrial settings. They contribute to enhanced control, safety, and efficiency in machine operations, providing reliable feedback and triggering specific actions based on the motion of machine components or the presence of objects.

Proximity switches encompass a range of operating principles, including the disruption of an electromagnetic field, capacitance sensing, or detection of a magnetic field. While industrial limit switches rarely directly control the final operating devices, they are commonly integrated into control systems. These limit switches are often wired through control relays, motor contactor control circuits, or utilized as inputs to programmable logic controllers (PLCs).

In certain applications, miniature snap-action switches find application as components within devices like photocopiers or computer printers. They ensure that internal components are correctly positioned for operation and prevent operation when access doors are opened, enhancing safety and protecting sensitive equipment.

The utilization of proximity switches and limit switches in various configurations and control systems enables precise control, reliable automation, and efficient operation across different industries and applications. They serve as critical components in ensuring proper functioning, optimizing performance, and safeguarding equipment integrity

Adjustable limit switches are installed on garage door openers to automatically stop the motor once the door has fully opened or closed, ensuring safe and precise positioning of the door.

In the case of numerical control machines like lathes, limit switches are utilized to establish maximum limits for machine parts and establish a reliable reference point for incremental movements. These switches enable precise control and prevent any unintended movements beyond the desired limits, contributing to accurate machining processes and enhanced operational safety.

A limit switch is a mechanical and activated by the movement of a specific machine component. It functions similarly to conventional switches, with contacts that undergo movement when an external plunger or lever is pressed.

Internally, an over-center spring mechanism triggers the switch to open or close in response to the gradual motion of the plunger or lever. This design ensures reliable and precise switching action, allowing for accurate control and detection of machine movements.

Functions of Limit Switches

• Detect and monitor the presence or absence of an object or target.

• Provide an electrical signal when a specified position, motion, or condition is reached.

• Control the movement of machinery or equipment by activating or deactivating certain functions based on predetermined positions or limits.

• Serve as safety interlocks to ensure that machines operate within safe operating parameters and prevent potential hazards.

Disadvantages of Limit Switches

• Limited precision: The accuracy of limit switches is often lower compared to more advanced position sensing technologies, making them less suitable for applications that require extremely precise positioning.

• Mechanical wear: Continuous mechanical operation of limit switches can lead to wear and tear over time, potentially affecting their reliability and lifespan.

• Limited sensing capabilities: Limit switches generally provide simple binary signals, lacking the ability to provide detailed or continuous feedback about the position or condition being monitored.

• Susceptible to environmental factors: Limit switches may be influenced by factors such as dust, debris, temperature variations, or humidity, which can affect their performance and require regular maintenance.

Advantages of Limit Switches

• Industrial machinery: Limit switches are widely used in various industrial applications, such as conveyor systems, packaging equipment, robotic arms, and assembly lines, to detect positions, limit movements, and ensure proper operation.

• Garage door openers: Limit switches are essential components in garage door systems to detect the fully raised or lowered position of the door and control the motor accordingly.

• Elevators and lifts: Limit switches are employed in elevators and lifts to determine the open and closed positions of doors, ensuring safe and efficient passenger transportation.

• HVAC systems: Limit switches are utilized in heating, ventilation, and air conditioning systems to monitor airflow, detect damper positions, or control fan operation based on specific conditions.

• Safety applications: Limit switches serve as safety interlocks in machinery to prevent operation when access doors are opened, ensuring the protection of operators and preventing accidents.

I hope you like above blog. There is no cost associated in sharing the article in your social media. Thanks for reading!! Happy Learning!!