What is pH sensor & How does it work?

pH sensor is one of the most important analytical measurement tool for measuring pH and is commonly used in water quality monitoring

What is pH sensor?

Explore the functionality of pH sensors, which play a crucial role in detecting and quantifying the acidity or alkalinity of liquids. Discover how these sensors contribute to maintaining optimal conditions and safeguarding the quality and integrity of various industrial processes, including wastewater treatment and manufacturing operations.

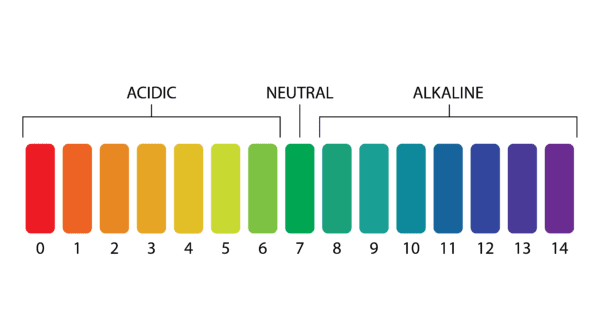

The pH scale, ranging from 0 to 14, serves as a measure of acidity or alkalinity.

A pH value of 7 signifies neutrality, while values above 7 indicate alkalinity and those below 7 signify acidity. Understanding pH is vital for industries utilizing cooling towers, boilers, manufacturing operations, pool maintenance, and environmental monitoring.

In the human body, a pH of 7.4 is crucial for optimal functioning, as any deviation toward acidity or alkalinity can disrupt the body’s equilibrium. Industrial processes across various sectors rely on pH analysis for purposes such as ensuring safety, monitoring product quality, and analyzing chemical reactions.

Unlike the simple pH experiments conducted in elementary school, these processes demand advanced instrumentation capable of withstanding harsh environments. At the heart of this instrumentation lies the pH sensor, a critical component for accurate pH measurement. Let’s learn the workings of a pH sensor and understand its role in industrial applications.

pH Sensor Operation

pH sensors play a crucial role in monitoring hydrogen-ion activity in a solution by utilizing electrodes. The measuring electrode specifically measures the ion exchange occurring through the gel layer formed on the glass membrane.

It then compares this measurement to the voltage recorded by the internal reference electrode. This comparison enables accurate determination of the pH level in the solution being analyzed.

By measuring and interpreting these electrical signals, pH sensors provide valuable insights into the acidity or alkalinity of a substance, making them indispensable in a wide range of industrial applications.

Understanding the components of a pH Sensor

Industrial pH sensors consist of specialized glass bodies with glass membranes that are designed to be compatible with the process liquids. These glass bodies house three electrodes: a measurement electrode, a temperature electrode, and a reference electrode. The reference electrode is a crucial part of the reference system and contains an electrolyte designed to remain neutral at pH 7.

When the sensor is immersed in the liquid, the special pH glass forms a sensitive gel layer on its surface. The measurement electrode generates a potential based on the hydrogen ion activity surrounding the gel layer. To ensure accurate measurements, the internal reference electrode needs to be electrically coupled with the solution through a liquid junction.

Different types of junctions, such as ceramic, open hole, or PTFE, are used depending on the sensor type. The potentials from each of these electrodes are essential for calculating the measured pH value. This calculation is typically performed by the transmitter or the head of a smart digital sensor, which provides a pH reading based on the gathered potentials.

It is crucial to properly care for these sensor components to maintain reliable potentials and ensure the accuracy of the pH sensor. Neglecting maintenance and care can lead to unreliable measurements and compromised accuracy.

4 Types of pH sensor

The pH sensor plays a vital role in maintaining the desired pH level for various applications, whether it involves strong acids or caustic bases. Depending on the specific liquid measurement requirements, there are different types of pH sensors available.

Combination pH Sensors: These sensors integrate the pH electrode and reference electrode into a single unit, providing accurate and convenient pH measurements. They are commonly used in laboratory settings and general-purpose applications.

Laboratory pH Sensors: Designed for precise pH measurements in laboratory environments, these sensors offer high accuracy and stability. They are often used in research, scientific experiments, and quality control applications.

Process pH Sensors: These sensors are specifically designed to withstand harsh industrial environments and continuous monitoring applications. They are resistant to chemical corrosion and can provide reliable pH measurements in industrial processes such as wastewater treatment, chemical manufacturing, and food processing.

Differential pH Sensors: These sensors are used to measure the pH difference between two points in a system. They are often employed in applications where pH variations across different locations need to be monitored, such as in pipelines or reactors.

Please note that choosing the right pH sensor type depends on the specific requirements of the application, the nature of the liquid being measured, and the environmental conditions in which it will be used.

Different applications require specific pH sensors, and pH measurements account for over 25% of quality-related measurements in process control. Reliable pH sensors and transmitters play a crucial role in plant optimization and process safety.

How to choose pH electrode?

pH sensors and transmitters find applications in various industries, including chemicals, water and wastewater, food and beverage, pharmaceuticals, power plants, primary oil and gas, and more.

The selection of a pH sensor depends on the specific application requirements.

For example, in the case of glass sensors, the choice of diaphragm and reference system can be customized to meet your needs. If you require a sensor that eliminates the risk of glass breakage or if the medium contains significant amounts of organic solvents, ISFET sensors can be a suitable option. On the other hand, enamel sensors are ideal when long-term stability and minimal maintenance are important considerations.

Benefits

The quality of water used in industrial processes is paramount to ensuring the excellence of the services and goods provided. Poor water quality can directly impact the return on investment, making it crucial to effectively manage water quality through various systems. Furthermore, compliance with rigorous environmental, industry, and safety standards heavily relies on maintaining and monitoring water quality.

By prioritizing water quality management, businesses can uphold their commitment to excellence while meeting regulatory requirements. Specializing in water pretreatment for manufacturing purposes enables effective management of water quality by removing impurities from influent water prior to its use in various manufacturing processes.

By eliminating these impurities, several benefits are achieved. Operating efficiency is enhanced, as the purified water ensures optimal performance and minimizes the risk of equipment damage. Heating and cooling systems operate more efficiently, leading to energy savings and improved cost-effectiveness.

Additionally, by maintaining compliance with water quality standards, businesses can uphold their reputation, meet regulatory requirements, and demonstrate their commitment to environmental sustainability and operational excellence.

Implementing a robust monitoring system for water quality can yield numerous benefits for businesses.

Some of these advantages include:

Reduce water waste: By closely monitoring water quality, businesses can identify and address issues such as leaks, excessive consumption, or inefficient water use, leading to reduced water waste and conservation of this valuable resource.

Energy savings: Optimal water quality management ensures that heating, cooling, and other processes involving water operate efficiently. This can result in energy savings by reducing the energy required to heat or cool water and improving overall process efficiency.

Meet supply chain sustainability requirements: Many industries have sustainability goals and regulations in place. Monitoring and maintaining water quality aligns with these requirements, allowing businesses to demonstrate their commitment to sustainable practices throughout their supply chain.

Preventing downtime: Water quality issues can lead to equipment breakdowns and system failures. By monitoring water quality parameters in real-time, businesses can proactively address any deviations or abnormalities, minimizing the risk of downtime and costly repairs.

Maintain a healthy workplace for employees: Clean and safe water is essential for providing a healthy workplace environment. Monitoring water quality ensures that water used for drinking, sanitation, and other employee-related purposes meets appropriate health and safety standards.

Reduce the use of hazardous chemicals: Poor water quality may necessitate the use of additional chemicals to treat or mitigate issues such as contamination or scaling. By maintaining good water quality, businesses can minimize the need for such chemicals, reducing potential environmental impacts and costs associated with their use.

Implementing an effective monitoring system for water quality empowers businesses to optimize their operations, improve sustainability practices, and protect the health and well-being of employees while reducing environmental impacts. Poor water quality can lead to health issues, dull hair, rough clothing, and dry skin for consumers.

pH sensors play a vital role in water quality management and treatment. Fluctuations in pH can be costly to fix, requiring more chemicals and resulting in downtime and higher expenses. Maintaining a neutral pH range of 6.5 to 8.5 is essential in wastewater treatment.

Choosing the right pH sensors, such as differential sensors with a third electrode, ensures accurate measurements for industrial applications like wet scrubbers.

Advantages of our pH measuring instruments

Advantages of pH measuring instruments include:

Accurate pH Measurement: pH measuring instruments provide precise and reliable pH readings, allowing for accurate monitoring and control of pH levels in various applications.

Wide Range of Applications: pH measuring instruments can be used in a wide range of industries and applications, including water and wastewater treatment, food and beverage production, pharmaceuticals, agriculture, research laboratories, and more.

Real-Time Monitoring: pH instruments provide real-time monitoring of pH levels, enabling prompt adjustments and interventions when pH values deviate from the desired range. This helps ensure optimal process performance and product quality.

Process Optimization: By monitoring and controlling pH levels, pH instruments contribute to process optimization, increasing efficiency, productivity, and yield in industrial processes.

Easy to Use: pH measuring instruments are typically user-friendly and easy to operate, allowing for convenient and hassle-free pH measurements.

Versatility: pH instruments often offer additional features such as temperature compensation, data logging capabilities, calibration options, and connectivity to external devices or computer systems, enhancing their versatility and functionality.

Quality Control and Compliance: pH measuring instruments assist in quality control by ensuring that pH levels meet specified standards and regulatory requirements. This is crucial in industries where pH plays a critical role in product quality and safety.

Cost Savings: Accurate pH measurements help optimize chemical dosing, reduce chemical waste, and prevent process inefficiencies, resulting in cost savings over time.

Longevity and Durability: pH measuring instruments are designed to be durable and withstand harsh environmental conditions, ensuring long-term performance and reliability.

Safety: pH instruments aid in maintaining safe working environments by enabling monitoring of potentially hazardous substances or processes where pH control is crucial.

pH measuring instruments provide so many advantages that contribute to improved process control, product quality, and operational efficiency in various industries.

Thanks for reading!! Happy Learning!!

I hope you like above blog. There is no cost associated in sharing the article in your social media. Thanks for reading!! Happy Learning!!